Only III+ generation pressurised water reactors are envisaged for the new nuclear source at the Dukovany site. The III+ generation reactor design uses the best available technology based on time-tested II/III generation types. The main differences from generations II/III:

- Standardised design reducing the time required for the licensing of each power plant, the investment costs, as well as construction time;

- Equipment with specific systems preventing the common cause failure and thereby prevention and reduction of the likelihood of serious accidents;

- Equipment with specific systems for managing and mitigating the consequences of severe accidents, to make sure that early or large releases of radioactivity to the environment are practically eliminated;

- Greater resistance to external hazards, including earthquake and aircraft crash;

- Greater availability (90% and more) and prolonged lifetime (at least 60 years);

- Provision of supporting services corresponding to primary, secondary, and tertiary regulation;

- Enabling greater degree of burnup of a nuclear fuel, and hence reduction of the quantity of radioactive waste generated.

The project will meet the safety requirements of Czech legislation as well as the safety requirements of the International Atomic Energy Agency (IAEA), the European Union, and the Western European Nuclear Regulators’ Association (WENRA).

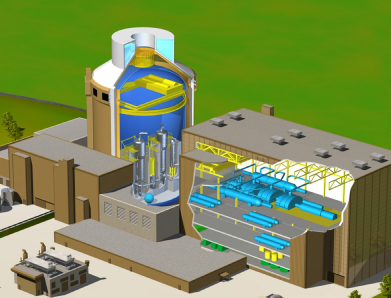

AP1000

A III+ generation pressurised water reactor made by Westinghouse, with an expected net power capacity of 1150 MWe (depending on site conditions).

The AP1000 project is the result of many years of development which has achieved optimisation in terms of investment and operating costs and a high level of safety, primarily through the use of passive elements. It has passed through the licensing process in the UK (Generic Design Assessment, 2017), in the US (Standard Design Certification, Combined Licence for the Vogtle project), as well as in China. Construction of two units at the Vogtle site is currently underway in the US (commissioning planned in 2023). Furthermore, 4 units were put into commercial operation in 2018 and 2019 at the Sanmen and Haiyang sites in China. The GRS Review was issued by the IAEA in 2009 and received EUR certification in 2007.

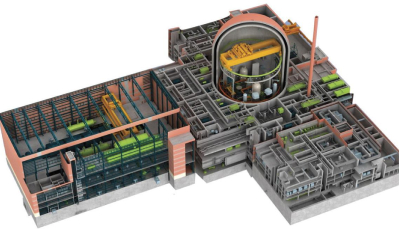

APR1000

A III+ generation pressurised water reactor made by KHNP, with an expected net power capacity of 1000 MWe (depending on site conditions).

The APR1000 is one of a number of Advanced Power Reactor (APR) projects. The project has been developed based on OPR1000s which are already in operation (e.g., Shin-Wolsong 1,2), incorporating safety features of the APR1400 project, or in its European version – EU-APR. The APR1400 has been licensed and is in operation in South Korea (the Shin-Hanul and Shin-Kori sites) and in the United Arab Emirates (the Barakah site). In the US, it received Standard Design Certification in 2019. The European EU-APR project (based on the APR1400) was developed to meet EUR and other European requirements. In 2017, the EU-APR project received EUR certification. The APR1000 project received the EUR certification in March 2023.

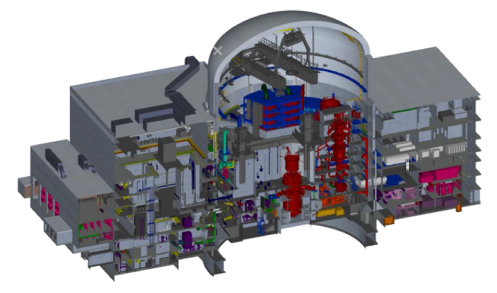

EPR1200

A III+ generation pressurised water reactor project made by EDF, with an expected net power capacity of 1150 MWe (depending on site conditions).

The EPR1200 is a scaled-down version of the EPR2 reactor, which has a capacity of approximately 1650 MWe. The EPR2 was developed on the basis of feedback from the design and construction of EPR reactors in order to optimise investment costs while maintaining a high level of safety. The EPR project has passed through the licensing process in Finland, France, the UK, China, and the US (US-EPR). Two EPR units have been in operation in China (Taishan 1,2) since 2018 and 2019, respectively, one EPR units in Finland (Olkiluoto 3), since 2022, and under construction are one unit in France (Flamanville 3 with an expected launch date of mid-2023) and two units in the UK (Hinkley Point C).

In 2009, the EPR project received EUR certification. In 2019, an affirmative statement was received from the French nuclear supervisor (ASN) concerning the principles of the safety solution for the EPR2. The safety report for the EPR2 licence was submitted to the French ASN supervisor in February 2021. At the end of May 2021, EDF submitted to the French government a comprehensive plan for the construction of 6 EPR2 units in France, with a decision expected within a few months. Compared to the EPR project, the EPR2 project has seen a simplification and standardisation of the design, including the use of a fully digital plant model and a modular method of construction. The main elements of the simplification are the use of a single prestressed reinforced concrete containment, with an internal steel lining instead of a double containment and the reduction of the number of divisions of the main safety systems from four to three, while maintaining a high level of safety.