A unique Israeli cooling system in Hodonín saves 57 million cubic metres of water every year, reducing its consumption by 97%

* The Hodonín power plant stabilises year-round supply of electricity and heat * This will be enabled by a new water-cooling method, using air in ventilator towers * The currently employed flow-through cooling, using water from the river, had limited capacity, particularly in summer * Biomass burning, which commenced in 2009, is now the main fuel * The cross-border supply of heat to Holíč, Slovakia is unique European terms After several months of testing, the brand-new cooling system at the Hodonín power plant has been transitioned into a one-year trial run. The advanced Israeli cooling-tower technology will cut cooling-water consumption by 97%, from 59 million cubic metres to less than 2 million per year. The ventilator cooling tower is broken up into 4 cells, each up to only 12.5 metres high, so that the facility does not disrupt the skyline. The Hodonín power plant is a low-emission ČEZ source that started to burn biomass in 2009.

Until now, the Hodonín power plant has used flow-through cooling, which significantly increased its dependence on the flow rate in the Morava River, from which it drew the cooling water, particularly during summer months. There was yet another limitation – the temperature and volume limits for returning the used water back to the river, or to the so-called Hot Channel. Thanks to an investment of tens of millions of crowns, the condensers of units TG3 and TG4 are now cooled by an Israeli system that is based on a closed-circulation circuit with a ventilator cooling-tower technology.

Whereas with flow-through cooling, the power plant needed more than 59 million cubic metres of water, today, it is less than 2 million cubic metres, meaning that with the installation of the cooling system, water consumption has been cut by 97 percent. “The Hodonín power plant is a Czech pioneer of low-emission production, having started to supply electricity and heat from biomass in 2009. In addition to 400 TJ of heat, we also produce 300 million kWh of green electricity ever year, covering the consumption of 90,000 households in Southern Moravia. In addition to the construction of environmentally friendly sources, the continuing decarbonisation of the Czech energy sector places an emphasis on maintaining a stable supply of energy. Until now, the Hodonin power plant has been one of the few operations using flow-through cooling, which considerably limited the reliability of supply, especially in summer. We have now remedied that weakness with the installation of this advanced Israeli technology,” says Martin Hrubý, Director of the Hodonín power plant.

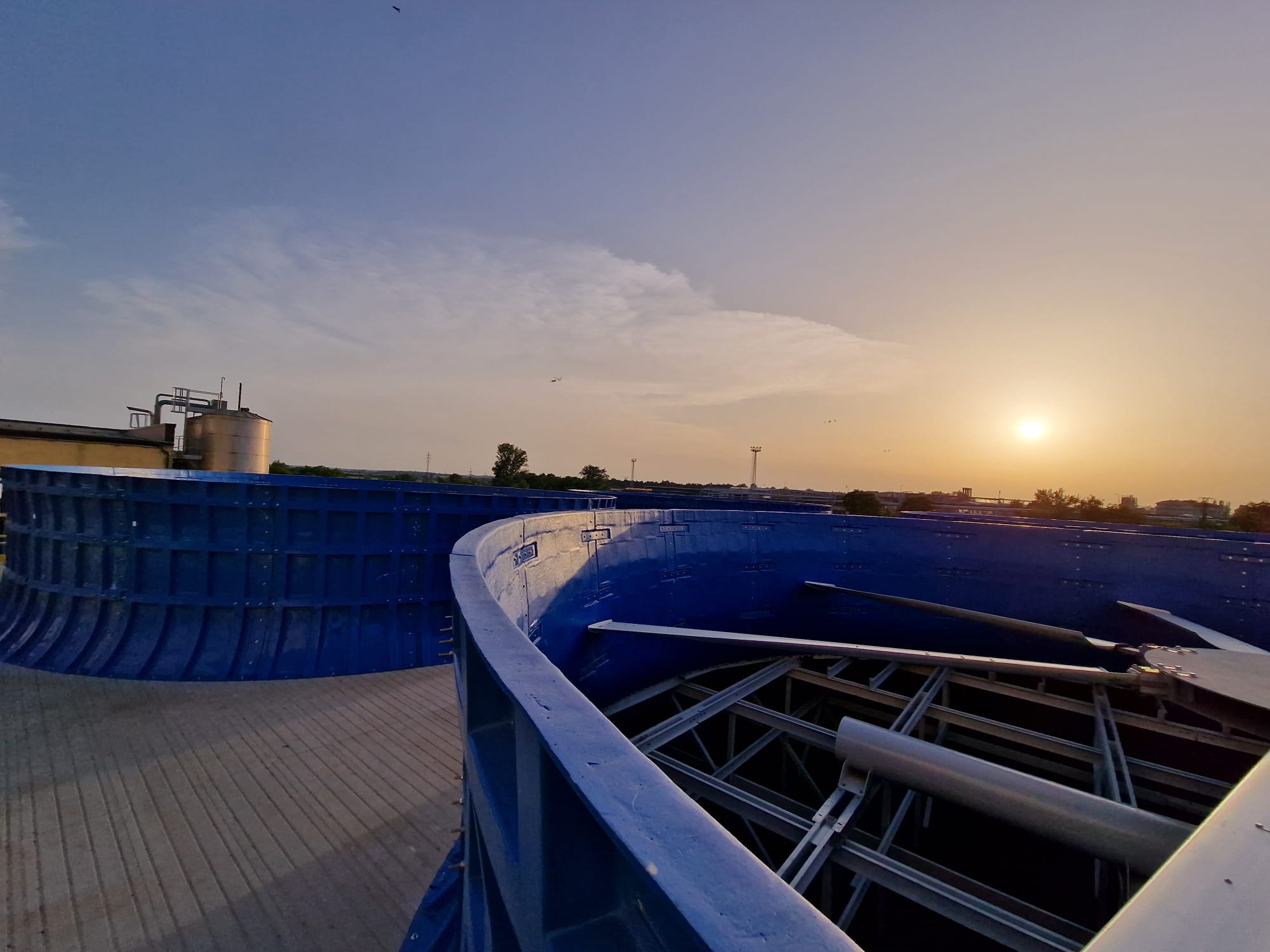

The most prominent feature of the circulation-cooling circuit is the ventilator cooling tower, taking up 30x30 metres of space. Each of its cells is equipped with a ventilator cell with a diameter of 11 metres, featuring seven blades. “With this solution, the height of the towers does not exceed the level of the main power plant hall, making them nearly invisible for most Hodonín residents. Only the water vapour rising from the cooling tower will be visible on colder days. Far more important, however, is ensuring stable operation of the power plant and saving water. By optimising the initial design of the technical solution, the cooling tower was moved closer to the source of heated water and the number of cells in the cooling tower was reduced from five to four. This, in addition to financial savings and increased cooling efficiency, helped accelerate construction, shortening the entire implementation time to a record ten months,” adds Jiří Ševčík, CEO of ČEZ Energetické služby, on behalf of the contractor that delivered the solution.

The launch of the cooling tower follows the previous upgrades of the Hodonín operations linked to increasing production from biomass, which is now burned at an annual volume exceeding 400,000 tonnes.

The Hodonín power plant was built between 1954-58, with individual units being commissioned one after another. With a capacity of 205 MW, it was the largest power source in Czechoslovakia at that time. The plant relied on inexpensive coal from lignite mines in the area and on cooling water from the nearby Morava River. At the beginning of the 21st Century, ČEZ started to convert power generation to biomass, which is now the only fuel used during regular operation. The Hodonín power plant is also unique in Europe, as it supplies cross-border heat, which travels from the plant across the Morava River to Holíč in Slovakia.

See how things are done in Hodonín

- Construction of the new cooling tower The unique Israeli cooling system in Hodonín saves 57 million cubic meters of water every year, reducing consumption by 97% | ČEZ Group – About us (cez.cz)

- Power and heat generation from biomass Virtual tour: ČEZ – coal-fired power plant at Hodonín (burning biomass) (cez.cz)

- CEZ Group Improves ESG Rating from CDP: Now Has a B for Climate Change and B- for Water

- CEZ one of first companies in Czechia to comprehensively monitor the impact of its business on nature

- INVESTORS WELCOME VALIDATION OF CEZ GROUP’S CARBON REDUCTION TARGETS

- SBTi experts confirm CEZ Group’s net-zero plans by 2040